Our history

La Essedue was born in 2000 as a valid manufacturer of furniture for campers, caravans, mobile homes, boating and all the derivatives of panel processing in general. Thanks to the thirty years of experience of its owners, the company immediately set itself up as a point of reference for the most important manufacturers of recreational vehicles and interior supplies.

To cope with the increasingly rapid growth and evolution of the market, our company follows its customers right from the design phase, trying to combine creativity and technology for a quality result, offering organization, experience and flexibility.

Production

With its structure of over 3,000 covered m2, Essedue fully satisfies the demands of the market, producing more than twenty complete furnishings daily. Always in the process of technological renewal, our company, thanks to the continuous search for machinery and equipment suitable for our needs, is able to reduce what are the normal processing times of the furniture components, without neglecting the attention to quality through continuous checks carried out during the production process. The latest generation machinery used by the company allows the projects provided by the customer to be carried out in detail and to offer alternative and innovative solutions to what were the classic woodworkings.

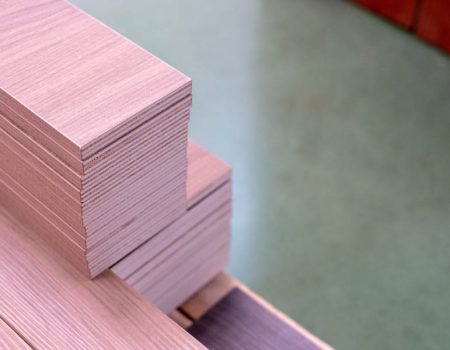

From nature, the raw material. The wood

Products

Doors

The ante range of Essedue Arredocamper is able to satisfy every need, being produced entirely within the company itself. They can be made on customer's request, whether they are flat, curved, in solid wood or with a combination of different materials or essences, always guaranteeing high quality, due to constant checks throughout the production cycle.

Hips

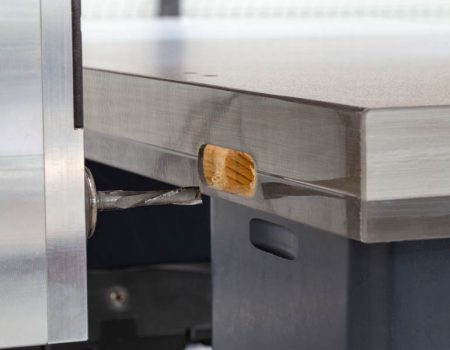

The sides of our production, normally used to delimit the complete piece of furniture, are made with a numerical control edging system capable of making any type of shape on any type of material and thickness, whether it is solid, honeycomb, laminated or MDF wood.

Curves and folding

At Essedue, curved furniture is built with an innovative system, which allows both a significant reduction in the final cost of the component, and a high production flexibility, ideal for the supply of spare parts. The folding system is used to have a folding angle of the furniture with a precise gradation, giving continuity to the folded detail without the help of external blocks or other joints.

Hollow and layered

The components of the furniture built with these types of technology, can be made in considerable thicknesses while maintaining their characteristic of lightness. Ideal for beds and doors, the hollow-core panels are suitable for any type of processing, adapted to the design according to the application required. The layered details, mainly used for the containment shoulders, are made with a central core which allows to guarantee a high level of sealing, both in the gluing process and in the fixing of other components to the shoulders themselves.

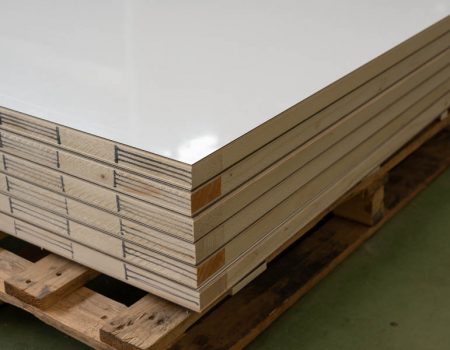

Tables and tops

The tables and tops, all of our production, can be made with different processing technologies regardless of thickness. It can vary from phenolic glued plywood, water resistant and ideal for kitchen and bathroom tops, to various structures with wooden or honeycomb frames. All the details can have a solid wood outline painted or thick edged in any shape and color.

Our Clients

Contact

- +39 0382 930783

- +39 0382 920822

- info@esseduearredocamper.it

- Via E. Mattei, 25 - Fraz. Divisa 27020 Marcignago (PV)